ERP Integration with External Platforms

At MasMade ERP Inc., we specialize in designing smart, automated connections between ERP systems and external platforms—including engineering tools like SolidWorks, CNC and plasma machines, Excel-based planning files, and other production or technical software. These integrations eliminate manual data entry, reduce errors, and enable seamless data flow across departments and systems.

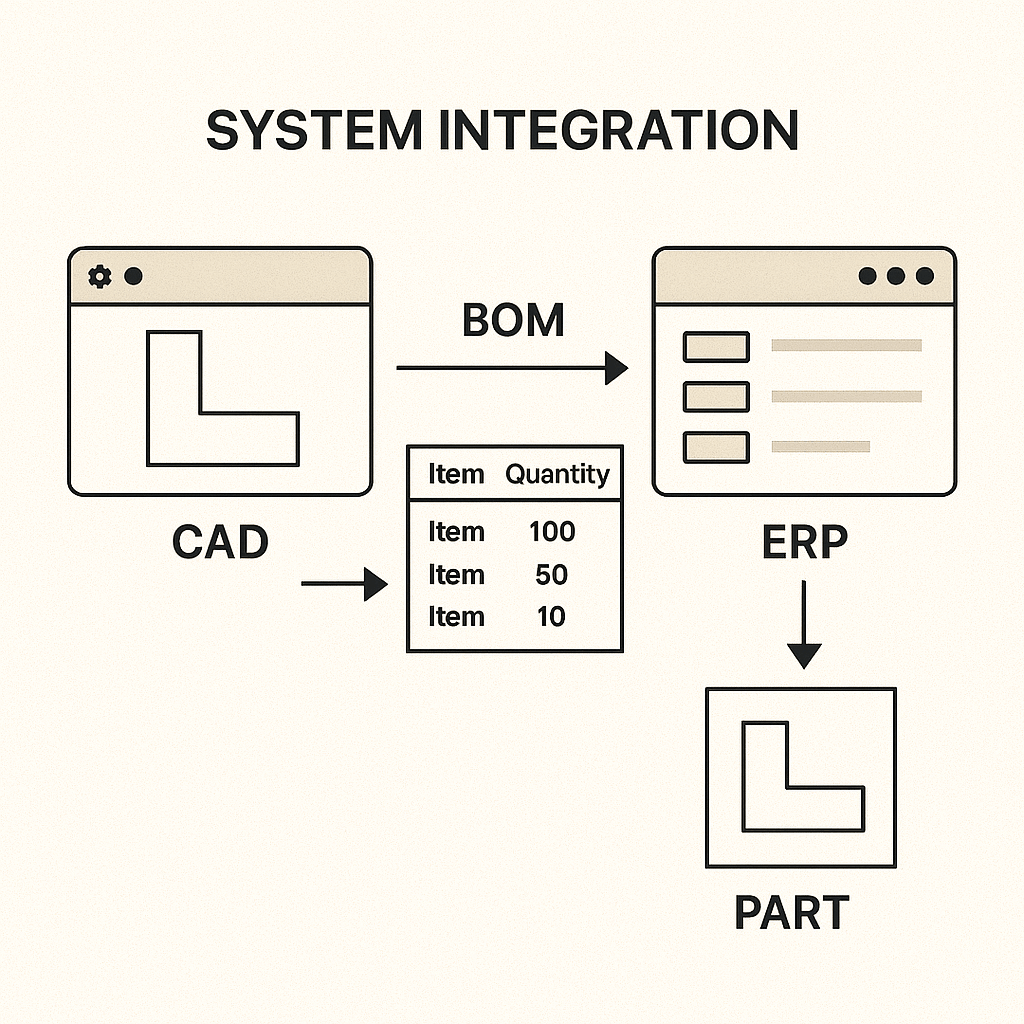

One of our standout projects achieved full integration between SolidWorks and our ERP platform, enabling real-time synchronization of bills of material (BOMs), routings, part drawings, and technical attributes — directly from CAD to ERP.

The Challenge

- Engineering teams were manually entering item details and technical specs into both SolidWorks and the ERP.

- BOMs, routings, and part drawings were created separately for the same parts, wasting time and risking inconsistencies.

- The absence of synchronization slowed down production readiness and added overhead to multiple departments.

Our Solution: CAD2BOM and Engineering Integration

We designed and implemented a CAD2BOM solution that creates a seamless interface between SolidWorks and the ERP system.

Key Features:

- 🧠 Automatic creation of BOMs and routings in ERP directly from SolidWorks assemblies and part files.

- 🧾 Auto-filled part properties (e.g., type, unit, category, and WO rules) based on predefined rules and item families.

- 📎 Auto-imported part drawings attached to ERP work orders for shop floor use.

- ⚙️ Routing templates applied dynamically based on material type (e.g., sheet vs. pipe).

- 📐 User-friendly SolidWorks dashboard to guide engineers in defining required properties for each item.

- 🔄 Bi-directional update triggers to reflect changes across systems instantly.

Implementation Strategy

- Mapped SolidWorks properties to ERP fields using a tailored ETM dashboard.

- Developed family/category logic to automatically determine default item attributes.

- Created dynamic routing logic linked to raw material properties.

- Defined a trigger system to export finalized engineering data to ERP in a controlled, consistent manner.

- Conducted collaborative sessions with Engineering Directors to ensure alignment with existing workflows.

Results & Operational Value

- 📉 Drastically reduced job preparation time by eliminating duplicate entry.

- ⚙️ Improved consistency in technical data across departments.

- 📁 Centralized visibility into job documents and part drawings.

- 🔄 Enabled fully automated flow from product design to production launch.

- 🧩 Created a repeatable framework for future engineering-ERP integrations.

How This Showcases Our Capabilities

This project demonstrates how MasMade ERP can:

- Build custom engineering-to-ERP interfaces without relying on third-party platforms.

- Design and implement ERP integrations with a variety of external platforms—including engineering tools or production equipment like CNC or plasma machines.

- Understand and map data flows between technical software and ERP environments to ensure alignment, accuracy, and efficiency.

- Deliver automation that saves time, improves accuracy, and enhances cross-departmental collaboration.

Facing a similar challenge in your organization?

We can help you overcome it with a tailored solution that fits your system, workflow and goals.

Let’s talk — your consultation is completely free.