ERP Intelligence Without the Overhead

At MasMade ERP Inc., we understand that not every business is ready for a full ERP implementation—due to budget, scale, or timing. That’s why we build customized, cost-efficient alternatives that deliver ERP-grade clarity and control, using the platforms you already have. When full ERP implementation is not yet affordable, high-impact solution can still transform a business.

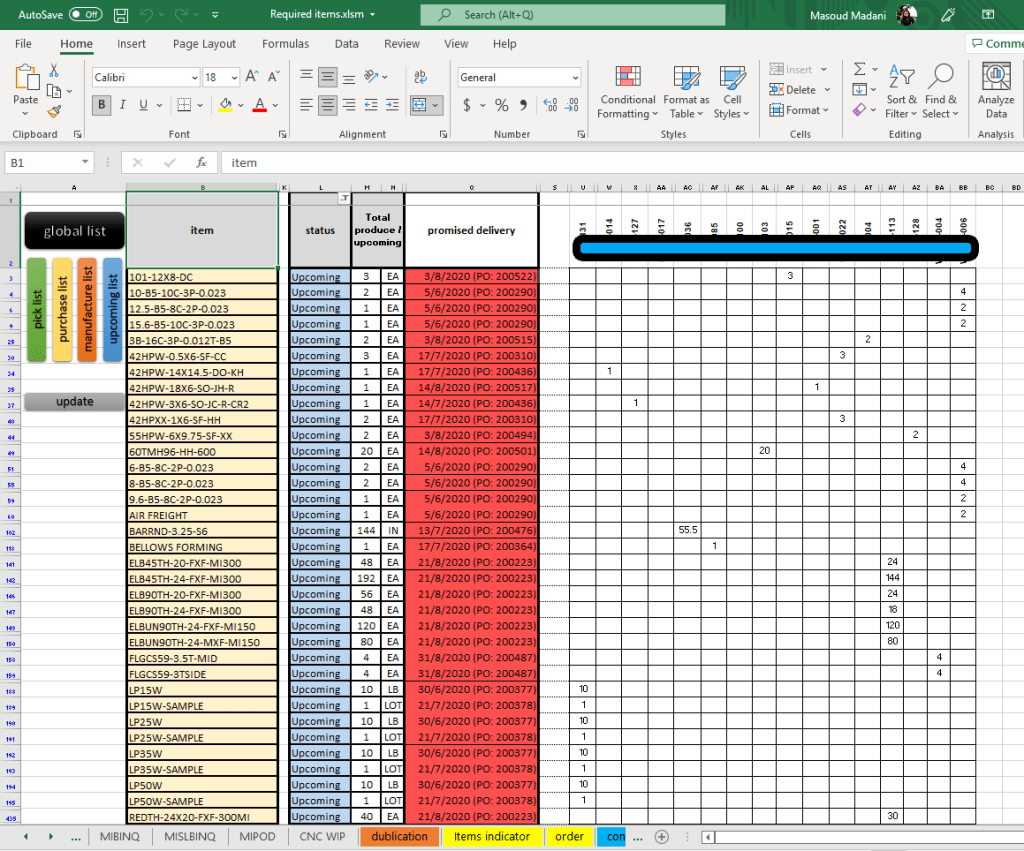

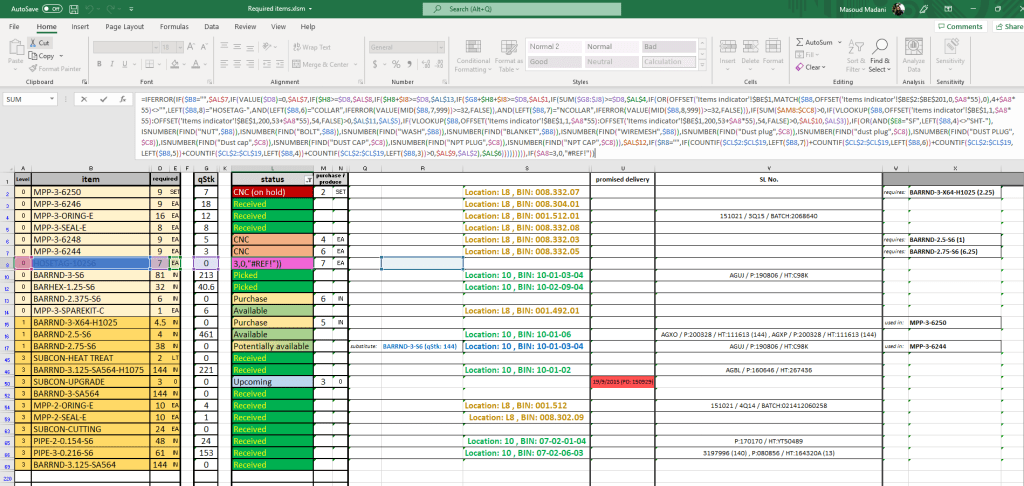

One of our early-stage solutions involved creating a powerful Material Resource Planning (MRP) system entirely within Excel—bridging Engineering, Inventory, and Purchasing to deliver ERP-level clarity with zero system overhead.

Project Snapshot: Smart Excel-Based MRP System

One of our most impactful solutions involved the development of an advanced macro-enabled Excel platform that replaced manual, paper-based workflows with intelligent, ERP-like functionality.

The Challenge

- Material planning was scattered across disconnected spreadsheets.

- Teams relied on memory and manual tracking to check stock and job readiness.

- Engineering, Inventory, and Purchasing operated in silos.

- No formal ERP system was in place—and no budget for one.

The Solution: ERP Functionality in Excel

We developed a centralized Excel-based MRP system with the following features:

- 🔄 Automated tagging of each material requirement:

- ✅ In Stock

- 🛒 To Purchase

- 🧰 To Fabricate

- 🚚 Incoming Delivery (with PO#, ETA, and location)

- 🧮 Intelligent BOM explosion up to 4 levels deep.

- 🔄 Real-time tracking of job material status and availability.

- 📊 Dashboards by department, project, and job allocation.

- 🔁 Substitution algorithms for compatible sizes and alloys.

All logic, automation, and data views were powered through Excel using VBA, formulas, and conditional formatting.

Outcome & Value Delivered

- 🔍 Real-time visibility into material status for Engineering and Procurement.

- 🕒 Hundreds of hours saved across departments.

- 🚫 Eliminated manual cross-checking and reduced shortages.

- 💡 Delivered ERP-style functionality—without needing to license or implement a full ERP system.

How This Showcases Our Capabilities

This project demonstrates how MasMade ERP can:

- Deliver impactful results using low-cost, available tools.

- Design and deploy custom alternatives to ERP platforms.

- Support growing businesses that need structure and visibility—without the complexity or cost of full ERP systems.

Facing a similar challenge in your organization?

We can help you overcome it with a tailored solution that fits your system, workflow and goals.

Let’s talk — your consultation is completely free.